Cutting Fluid and Industrial Lubricants Certifications

In an era where industries are driven by precision, efficiency, and sustainability, the role of lubricants has never been more critical. Lubricants are the lifeblood of machinery, ensuring smooth operations and prolonging the lifespan of equipment. To harness the full potential of lubricants, obtaining certifications in lubricant management is essential. These certifications are more than just qualifications; they are pathways to optimizing lubricant usage and driving operational excellence.

Hai Lu Jya He (HLJH) stands as one of the global leaders in the manufacturing of cutting oils and industrial lubricants. Our commitment to quality and innovation is reflected in the certifications we pursue, ensuring that our products meet the highest standards in the industry.

There are certifications that can protect your benefits and product quality - RoHs, Reach, TGRS, TDS and SDS. Basically, you will get SDS and TDS from your industrial lubricants supplier. We’re going to show you the details of certifications as below. Through product certifications that make sure the goods are safely to be used.

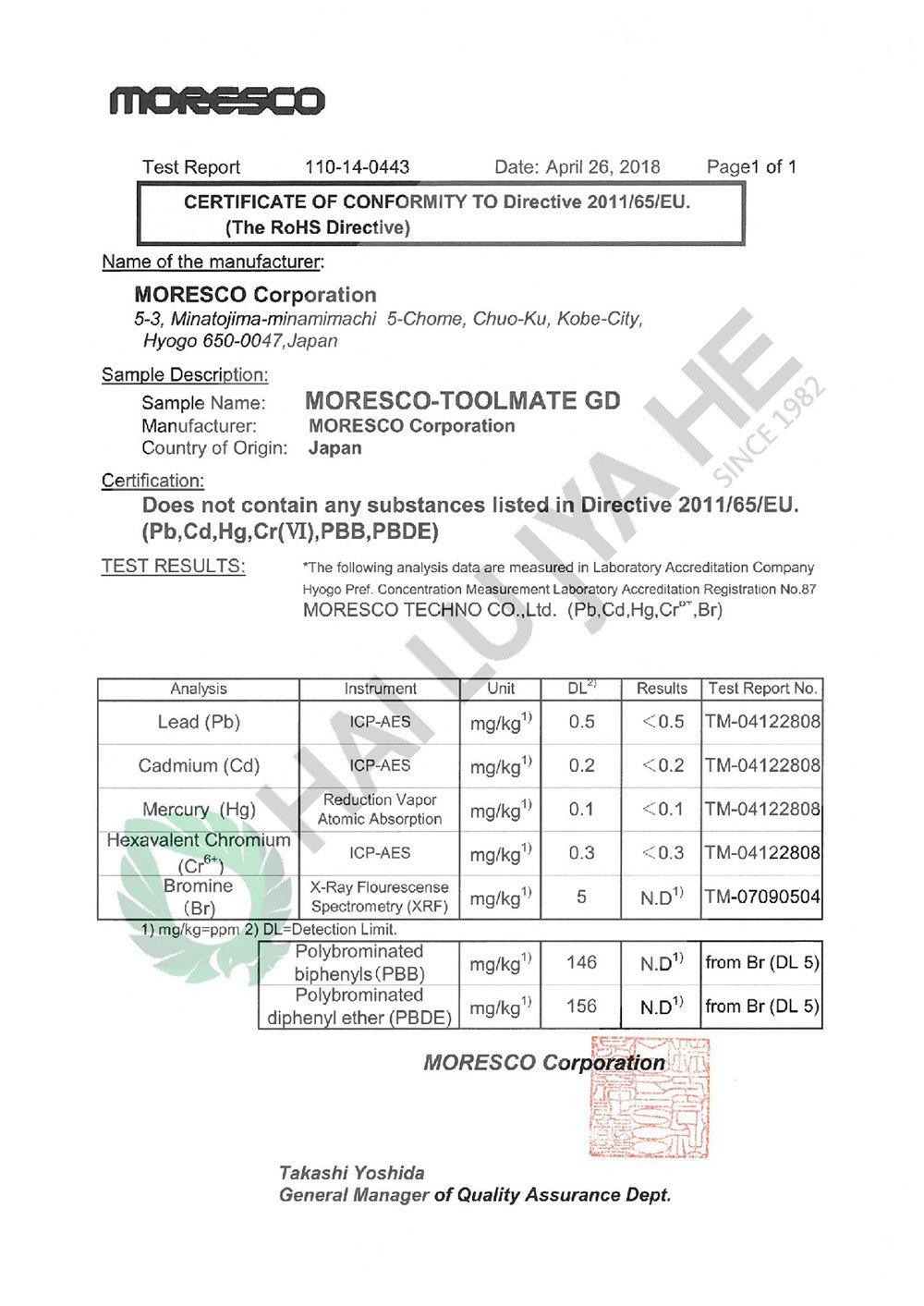

● RoHs (RESTRICTION OF HAZARDOUS SUBSTANCES)

RoHS stands for Restriction of Hazardous Substances, and impacts the entire electronics industry and many electrical products as well. The original RoHS, also known as Directive 2002/95/EC, originated in the European Union in 2002 and restricts the use of six hazardous materials found in electrical and electronic products. All applicable products in the EU market since July 1, 2006 must pass RoHS compliance.

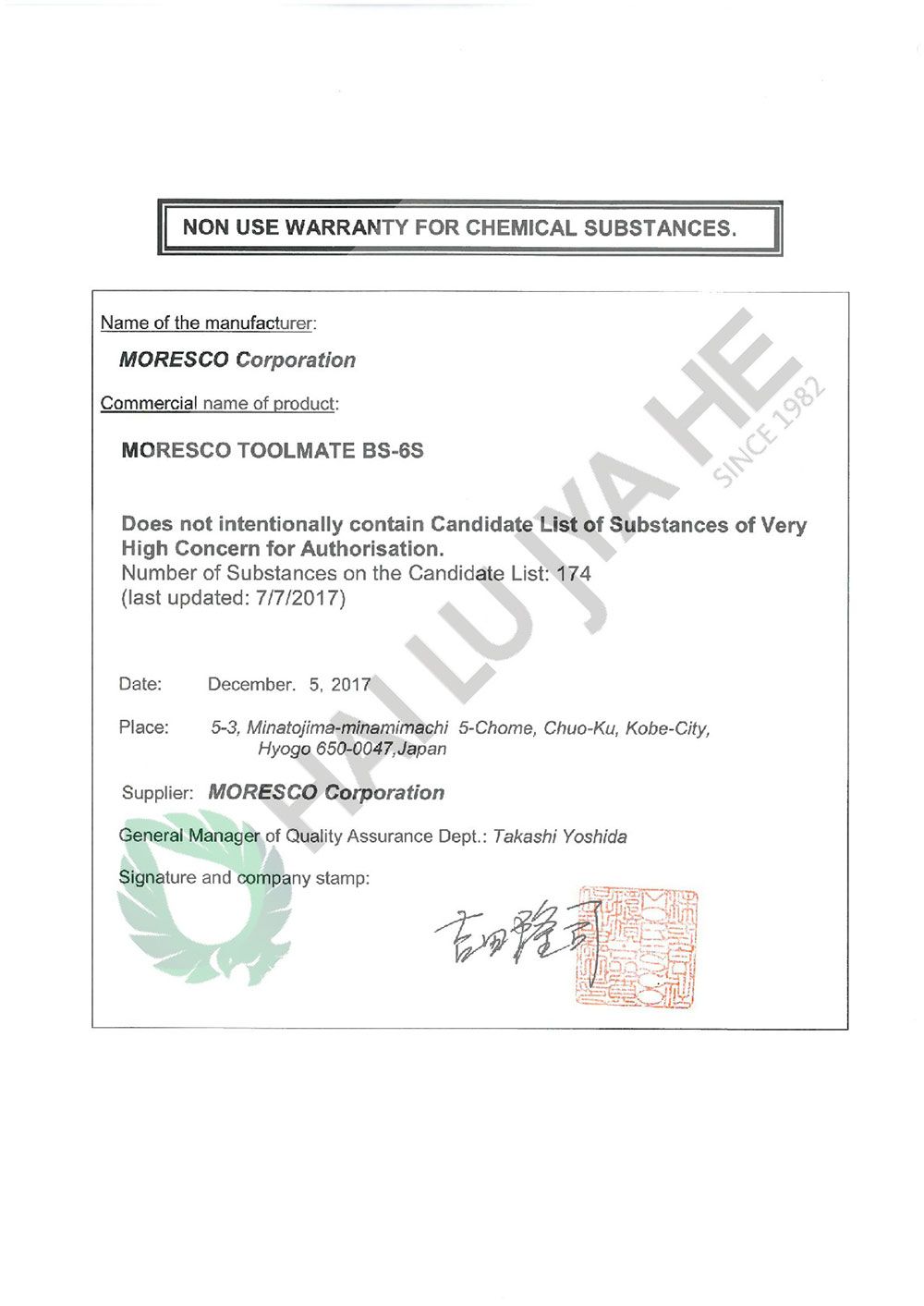

● Reach

Reach stands for Registration, Evaluation, Authorisation and Restriction of Chemicals,is a regulation of the European Union, adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals, while enhancing the competitiveness of the EU chemicals industry. It also promotes alternative methods for the hazard assessment of substances in order to reduce the number of tests on animals.

In principle, REACH applies to all chemical substances; not only those used in industrial processes but also in our day-to-day lives, for example in cleaning products, paints as well as in articles such as clothes, furniture and electrical appliances. Therefore, the regulation has an impact on most companies across the EU. If the risks cannot be managed, authorities can restrict the use of substances in different ways. In the long run, the most hazardous substances should be substituted with less dangerous ones.

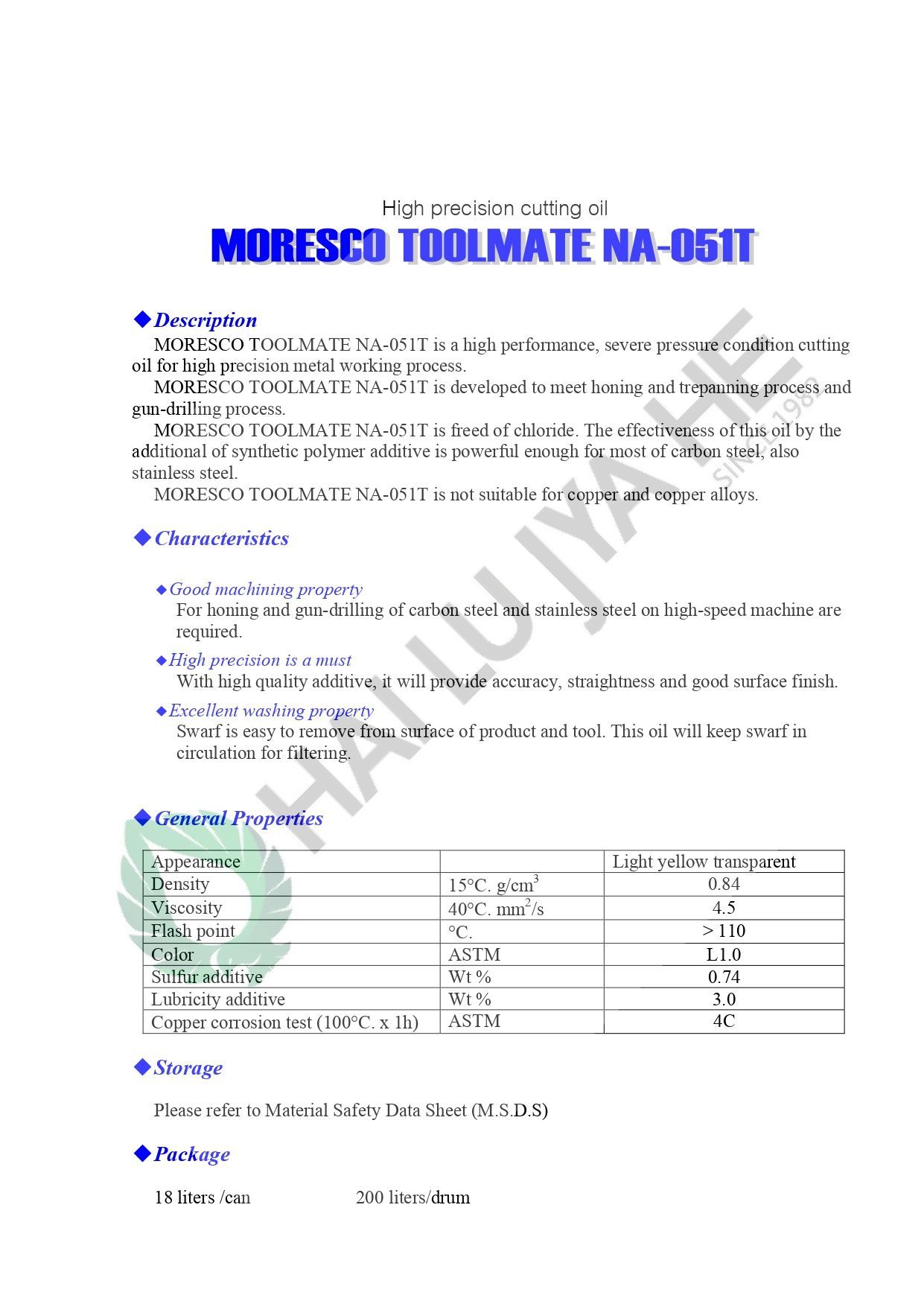

● TDS (TECHNICAL DATA SHEET)

A Technical Data Sheet is a document from a supplier, which describes the technical data of a raw material. The TDS shall normally been approved before any tests of the material ,and contain any information that is important for our use of the material in the intended application.

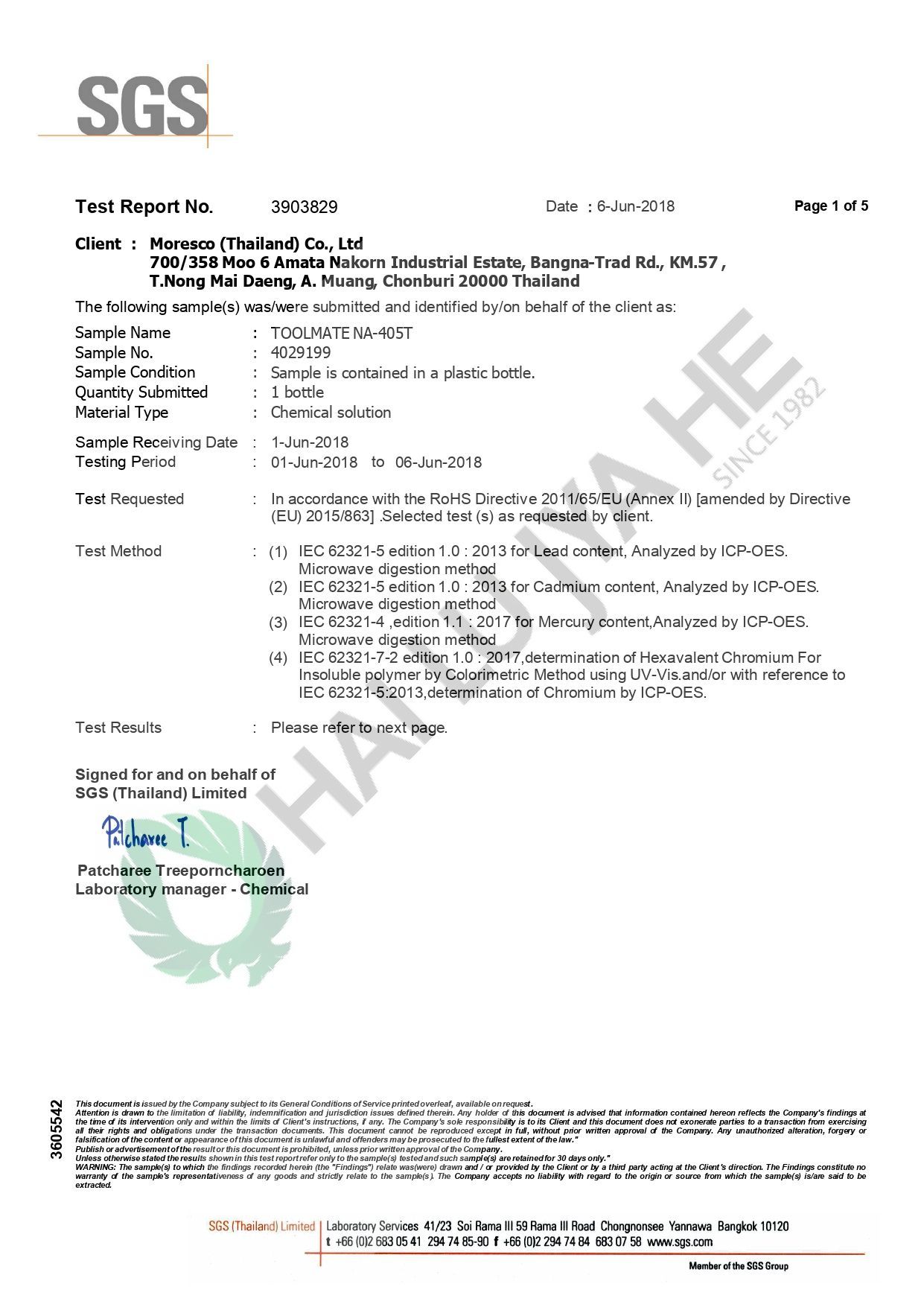

● SGS

SGS is a multinational company headquartered in Geneva, Switzerland which provides inspection, verification, testing and certification services. The core services offered by SGS include the inspection and verification of the quantity, weight and quality of traded goods, the testing of product quality and performance against various health, safety and regulatory standards, and to make sure that products, systems or services meet the requirements of standards set by governments, standardization bodies or by SGS customers.

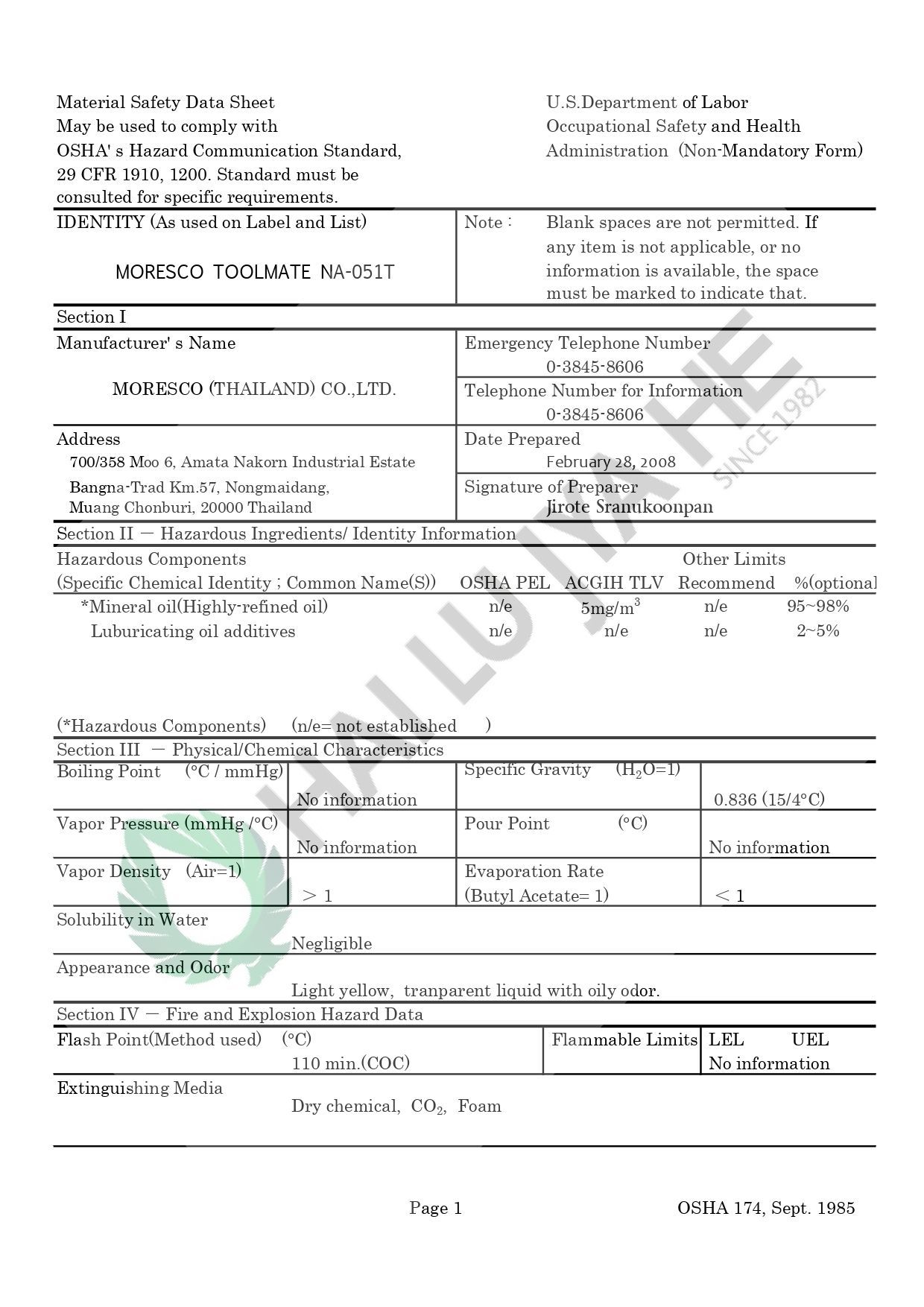

● SDS (SAFETY DATA SHEET)

A safety data sheet (SDS), is a document that lists information relating to occupational safety and health for the use of various substances and products. SDSs are a widely used system for cataloging information on chemicals, chemical compounds, and chemical mixtures. SDS information may include instructions for the safe use and potential hazards associated with a particular material or product, along with spill-handling procedures. SDS formats can vary from source to source within a country depending on national requirements.

A SDS for a substance is not primarily intended for use by the general consumer, focusing instead on the hazards of working with the material in an occupational setting. There is also a duty to properly label substances on the basis of physico-chemical, health or environmental risk. Labels can include hazard symbols such as the European Union standard symbols. The same product (e.g. paints sold under identical brand names by the same company) can have different formulations in different countries. The formulation and hazard of a product using a generic name may vary between manufacturers in the same country.

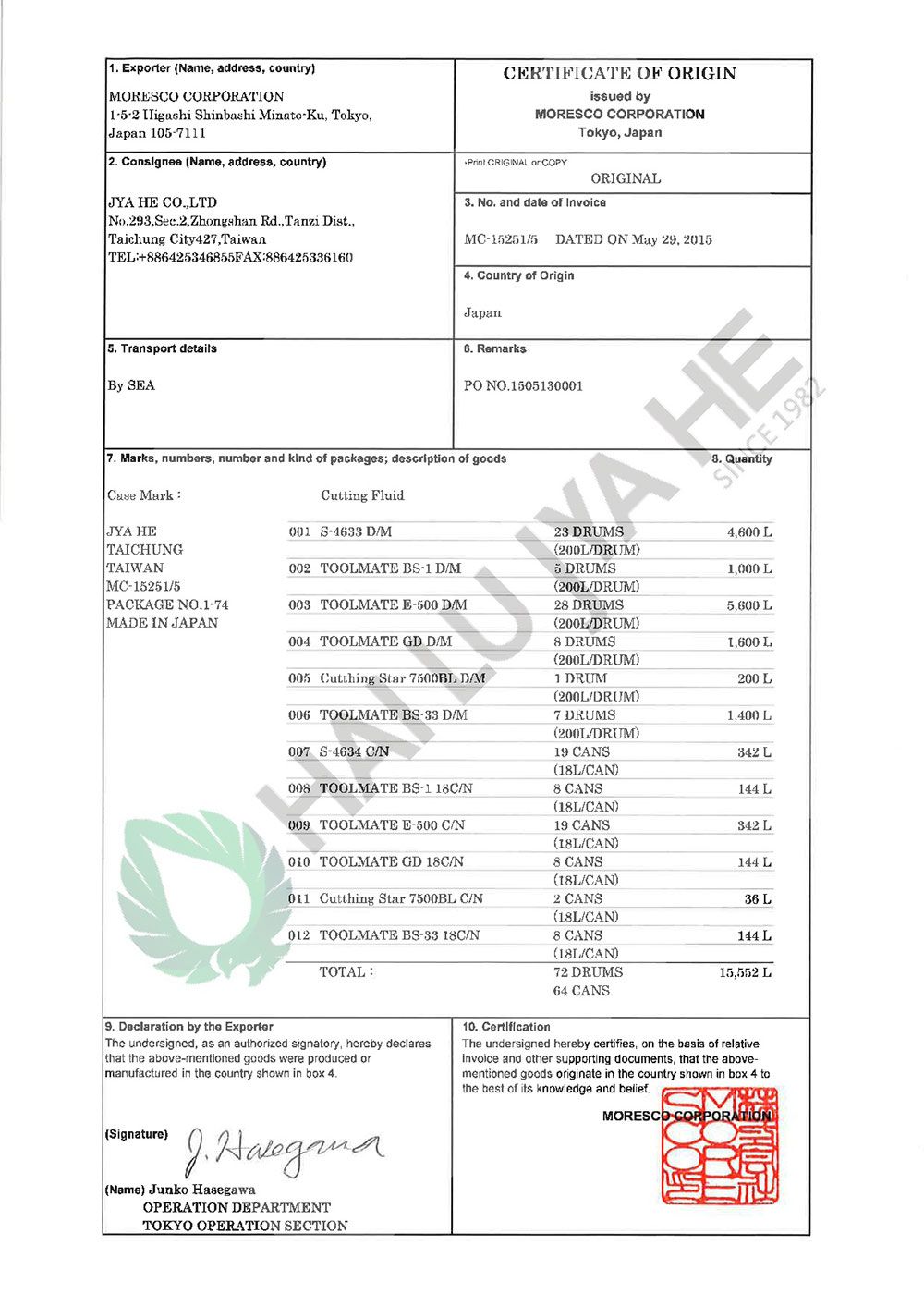

● COO - CERTIFICATE OF ORIGIN

A Certificate of Origin (CoO) is a document that evidences that the goods in your export shipment were produced, manufactured, or processed in a particular country. It requires standard information, like the exporter, consignee, shipment routing, and goods description.

It also includes two additional sections specific to the document:

1. Exporter Declaration - A declaration by the exporter to the inspector vouching for product details and the country of manufacture.

2. Inspection Certificate - A certificate completed by a state employee or an outsourced agency signifying that the goods were inspected.