The Advancement of High-Entropy Alloys: Unlocking the Link Between Next-Generation Metalworking Materials and Cutting Lubrication

As materials science continues to evolve, High-Entropy Alloys (HEAs) are rapidly becoming a key topic in the fields of metal processing and cutting lubrication. These innovative materials are widely regarded as a breakthrough beyond the limits of traditional alloys due to their exceptional wear resistance, corrosion resistance, and thermal stability. For industries focused on metalworking lubricants, cutting fluids, and waste oil treatment, understanding the development trends of HEAs not only provides insights into the future of machining technology but also aids in developing lubrication solutions tailored to high-performance materials.

Structure and Performance of High-Entropy Alloys

Traditional alloy design typically centers around one principal element, enhanced by the addition of small amounts of secondary elements. In contrast, high-entropy alloys disrupt this conventional approach by combining five or more principal elements in near-equiatomic ratios. This composition generates high configurational entropy, which stabilizes the crystal structure and results in superior mechanical strength and thermal stability.

The outstanding properties of HEAs derive from four fundamental mechanisms: the high-entropy effect, lattice distortion, sluggish diffusion, and the cocktail effect. These characteristics allow HEAs to demonstrate excellent resistance to wear, corrosion, high temperatures, and radiation in practical applications, making them especially suitable for aerospace, defense, nuclear, and other advanced manufacturing industries.

Current Applications of High-Entropy Alloys

HEAs have already found applications across several high-tech industries. In aerospace, they are capable of withstanding extreme temperature variations and high-pressure environments. In the nuclear field, their radiation resistance contributes to extended service life of critical components. For defense applications, HEAs are used in impact- and wear-resistant coatings to enhance the durability of weapon systems.

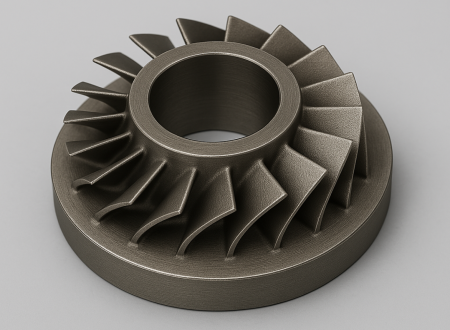

Moreover, high-entropy alloys are widely applied as surface coatings for high-performance cutting tools, significantly improving wear resistance and service life. In addition to bulk materials, HEAs are frequently used in the form of thin films or coatings, playing a crucial role in protecting tool surfaces in precision machining and high-speed cutting systems.

Lubrication Challenges in HEA Machining

As the adoption of HEA materials grows in manufacturing environments, it also presents new challenges for cutting fluids and lubricants. The extreme hardness and stability of HEAs can accelerate tool wear and generate significant heat during machining, which in turn causes rapid degradation of cutting fluids and a decline in their performance.

Therefore, future cutting lubricants must offer enhanced extreme pressure and anti-wear performance to effectively manage friction and thermal loads. Additionally, lubricants will need improved thermal stability and oxidation resistance to cope with prolonged high-pressure operations. The ability of lubricants to maintain stable oil films and adhere effectively to HEA surfaces will become a key consideration in future formulation strategies.

Future Outlook: Integrating High-Entropy Alloys and Lubrication Technologies

Looking ahead, the commercialization of HEAs is expected to deepen their integration with industrial lubrication applications. Lubricant suppliers and metalworking professionals should consider the following strategies:

First, develop cutting fluids and EP additive formulations tailored to the machining characteristics of HEAs.

Second, conduct in-depth studies on the impact of different HEA compositions on lubricant thermal degradation and waste oil byproducts.

Third, enhance the stability and adhesion performance of lubricants on HEA surfaces.

Hai Lu Jya He has years of experience in metalworking lubrication and is well-versed in both materials applications and cutting lubrication solutions. As HEA technologies rapidly evolve, we continue to integrate lubricant formulation development with on-site application expertise, helping clients optimize machining processes and stay competitive in the era of next-generation materials.

◆ Source: MDPI

◆ Reference: https://www.mdpi.com/1099-4300/25/1/73

The Advancement of High-Entropy Alloys: Unlocking the Link Between Next-Generation Metalworking Materials and Cutting Lubrication | ISO 9001:2015 Certified Industrial Lubricants Manufacturer And Supplier Since 1982 | HLJH

Located in Taiwan, HAI LU JYA HE CO., LTD has been an industrial lubricant manufacturer and supplier. Main products, include metalworking fluids, industrial lubricants, soluble cutting oils, semi-synthetic cutting oils, synthetic cutting fluids, neat cutting oils, rust preventive oils, slideway oils and hydraulic oils, which can reach 150 tons of cutting fluids per month.

HAI LU JYA HE Co., Ltd. (HLJH) have been focusing on manufacturing and marketing the industrial lubricants more than 30 years. Our fundamental belief is to make a harmful, friendly with lives, businesses, and leaving a lasting legacy for generations to come. We offer metalworking fluids (water-based cutting fluid, neat cutting oil), rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain. Our fundamental belief is to offer harmful and friendly products such as water-based cutting oils, neat cutting oil, rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain.

HLJH has been offering customers high-quality metalworking oils and fluids, both with advanced technology and 39 years of experience, HLJH ensures each customer's demands are met.